For More Details of the Option Click the Red Model Button

| Model | Image | Details | Icons | Wt. |

|---|---|---|---|---|

| D-150-EXT-SMY |

|

Steel Mesh D-150 Series Side Extensions 64-15/16 In. x 43-1/… | 90 Days Limited Warranty | 37 |

| D-200-EXT-SMY |

|

Steel Mesh D-200 Series Side Extension 64-15/16 In. x 56-1/8… | 90 Days Limited Warranty | 40 |

| D-250-EXT-SMY |

|

Steel Mesh D-250 Series Side Extensions 64-15/16 In. x 69-1/… | 90 Days Limited Warranty | 45 |

| D-300-EXT-SMY |

|

Steel Mesh D-350 Series Side Extensions 64-15/16 In. x 81-5/… | 90 Days Limited Warranty | 50 |

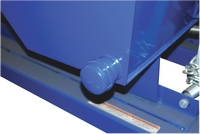

| D-DPLG-2 |

|

Factory Installed Welded Steel 2 In. Threaded Drain Plug Lef… | 30 Days Limited Warranty | 2 |

| D-DPLG-75 |

|

Factory Installed Welded Steel 3/4 In. Threaded Drain Plug L… | 30 Days Limited Warranty | 1 |

| D-PIN |

|

Factory Installed Welded Steel Fork Retaining Pin For D-Styl… | 90 Days Limited Warranty | 5 |

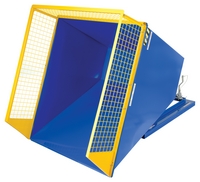

| D-TILT |

|

Steel Sideways Tilt Fork Attachment For D Style Hoppers Yell… | 90 Days Limited Warranty | 130 |

| Model Number | Image | Description | Wt. (lbs.) |

| Caster Options |  |

Caster options for D style hoppers | - |

| Optional Lids |  |

Lid options for D style hoppers | - |

| PLID-INSTALL |  |

Vestil Optional Factory Installation of PLID | Factory Installation of Hopper Lid |

| LEKP |  |

Welded leak proof Option | 5 |

| LUG |  |

(4) Lifting Lugs (Welded) One on Each Corner | 23 |

|

*D-DPLG-75 and D-DPLG-2 options includes leak proof chute welds |

|||

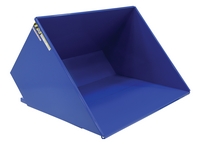

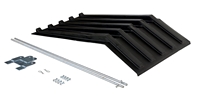

OPTION: D-150-EXT-SMY

Side Extensions, are great addition for material handling and construction facilities. The extended sides are constructed of steel mesh for high strength durability during transference of goods, while the yellow painted finish delivers great visibility.

| Side Extensions For "D" Style Hoppers | |||

| Model Number | Extension Height |

Works With Hopper Series |

Wt. (lbs.) |

| D-150-EXT-SMY | 15-11/16" | D-150 | 37 |

| D-200-EXT-SMY | 15-11/16" | D-200 | 40 |

| D-250-EXT-SMY | 15-11/16" | D-250 | 45 |

| D-300-EXT-SMY | 15-11/16" | D-300 | 50 |

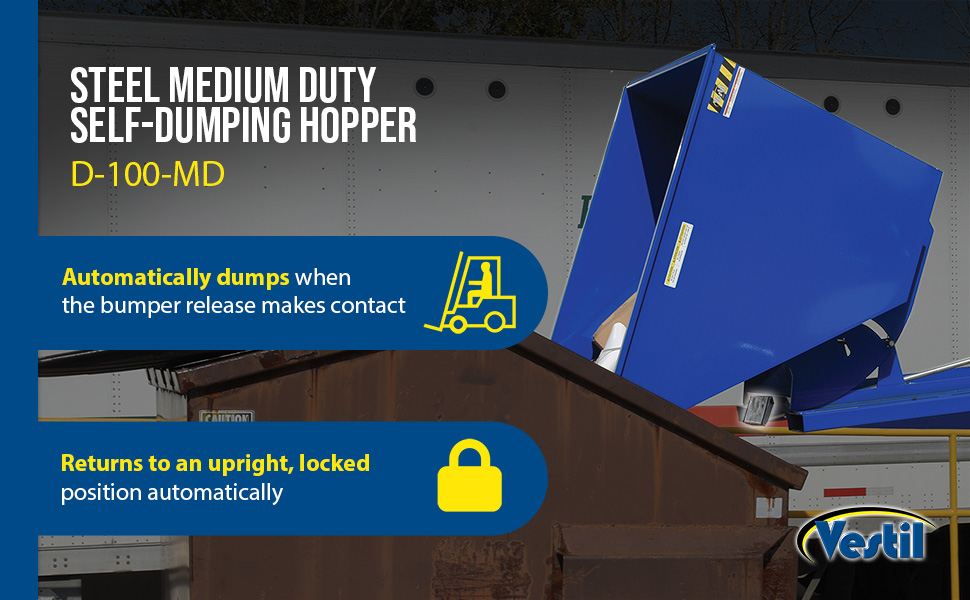

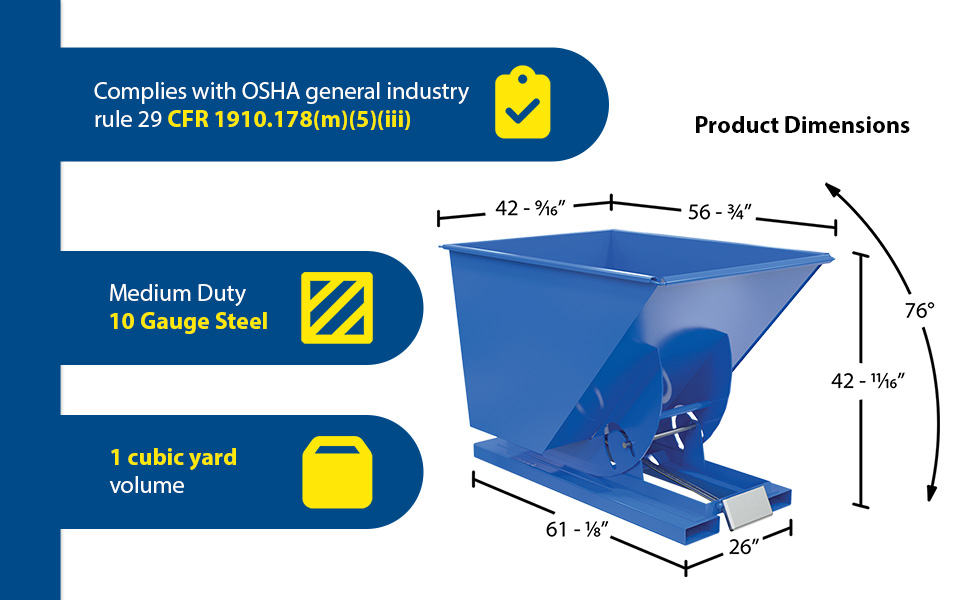

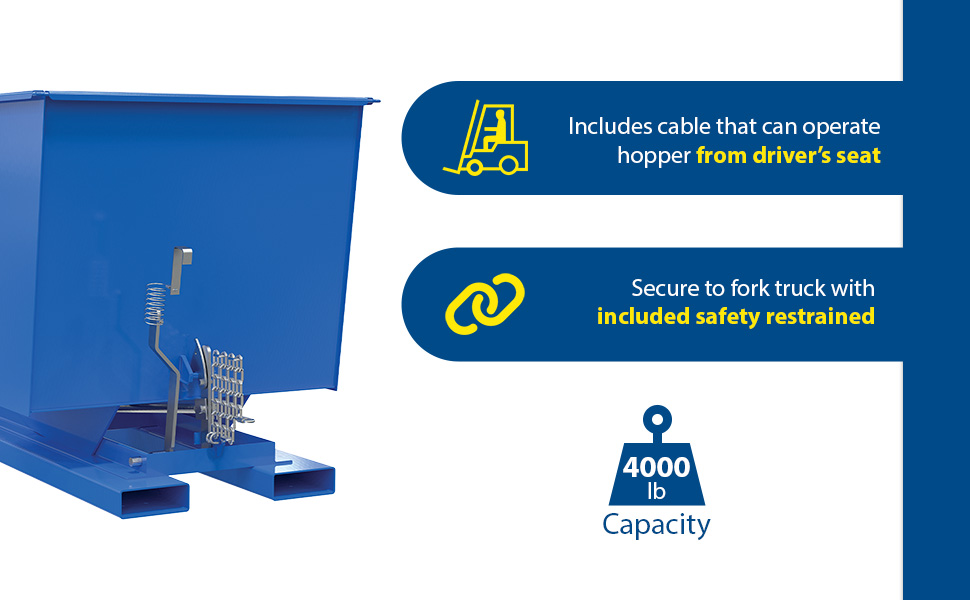

Hopper automatically dumps when bumper release contacts the front of the dumpster. Hopper returns to an upright and locked position automatically after it dumps. Also includes a cable that may be operated from the seat of the fork truck to manually dump the hopper. A safety restraint is provided to secure the hopper to the fork truck. Usable fork pockets are 7-1/2"W x 2-1/2"H. Self-dumping hoppers facilitate compliance with OSHA General Industry rule 29 CFR 1910.178(m)(5)(iii) by allowing lift truck operators to remain at the controls of their truck throughout the dumping process. Optional leak proof design sold separately. D-25, D-33, D-50, D-75, and D-100 are stackable if you stack the top hopper turned 90 degrees from the bottom. Blue baked-in powder-coated toughness is standard.

Hopper automatically dumps when bumper release contacts the front of the dumpster. Hopper returns to an upright and locked position automatically after it dumps. Also includes a cable that may be operated from the seat of the fork truck to manually dump the hopper. A safety restraint is provided to secure the hopper to the fork truck. Usable fork pockets are 7-1/2"W x 2-1/2"H. Self-dumping hoppers facilitate compliance with OSHA General Industry rule 29 CFR 1910.178(m)(5)(iii) by allowing lift truck operators to remain at the controls of their truck throughout the dumping process. Optional leak proof design sold separately. D-25, D-33, D-50, D-75, and D-100 are stackable if you stack the top hopper turned 90 degrees from the bottom. Blue baked-in powder-coated toughness is standard.